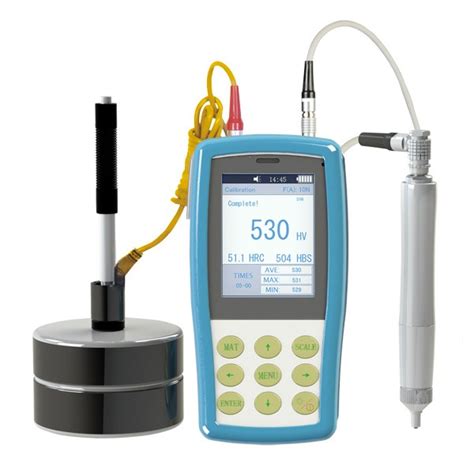

ultrasonic hardness testing method|ultrasonic contact impedance hardness tester : traders The portable, non-destructive nature of the ultrasonic hardness testers make it perfect for some applications, including: 1. Maintenance of built-in components that cannot be moved 2. . See more WEB30 de nov. de 2023 · O óbito ocorreu por volta das 6h30 de quarta-feira (29) após uma falência múltipla dos órgãos, ocasionada por complicações de uma cirurgia bariátrica. .

{plog:ftitle_list}

25 de jun. de 2016 · 156. Curtidas Recebidas: 29. Curtiu: 135. Sexo: Masculino. Cubos: 669.00. Nick: ender_crazy. Clan: RvT. #1 heltonsilva, 25 Junho 2016. Vi essa ideia de .

Ultrasonic Hardness Testing is also known as Ultrasonic Contact Impedance. The Ultrasonic Contact Impedance method has been around for over 50 years and was developed heavy and/or unmovable parts where traditional testing methods could not be used or would . See moreThe fact that this testing method does not damage the test sample is just one of the advantages of the UCI method. Some other advantages of ultrasonic hardness testersinclude: 1. . See moreThe portable, non-destructive nature of the ultrasonic hardness testers make it perfect for some applications, including: 1. Maintenance of built-in components that cannot be moved 2. . See moreThe UCI method (Ultrasonic Contact Impedance or modified Vickers procedure) – first put to use in 1965 under the name “SonoDur” - electronically evaluates each Vickers hardness test indentation in a fraction of a second and .

1.1 This test method covers the determination of comparative hardness values by applying the Ultrasonic Contact Impedance Method (UCI Method). 1.2 The values stated in . An ultrasonic hardness tester is one of the most common testing solutions available today. But another hardness tester that you can consider is the bench top hardness tester type. Knowing what makes the difference .The MICRODUR instruments (Krautkramer) work according this method, the so-called UCI (Ultrasonic Contact Impedance) method. Another well-known principle for portable hardness testers is the rebound method. The UCI (Ultrasonic Contact Impedance) method is a portable and versatile modern technique for testing hardness. It operates on the premise that the frequency of an oscillating rod changes when it penetrates a sample. The UCI technique is ideal for fine-grained materials, narrow components, and components with hardened surfaces. Understanding How .

The leading Ultrasonic Contact Impedance measurement system with advanced capabilities . Combination with another testing method Leeb, Portable Rockwell (PRT) Connectivity . The 3 Most Reliable Portable Hardness Testing .UCI Method for Hardness Testing: The UCI hardness measuring method complies to ASTM A1038. The ultrasonic contact impedance (UCI) probe is purposed to be used for hardness measuring testing areas with minimal thickness (starting from 1 mm). It . 1.1 This test method covers the determination of comparative hardness values by applying the Ultrasonic Contact Impedance Method (UCI Method). 1.2 The values stated in SI units are to be regarded as standard.

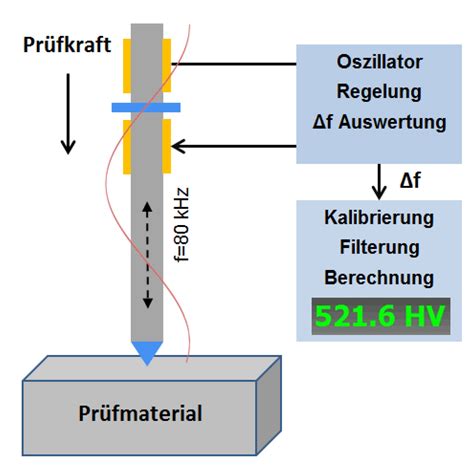

2 UCI hardness test method 2.1 The UCI measuring principle As the name ‘ultrasonic contact impedance’ suggests, the principle is based on the use of ultrasound excitation to determine the hardness of the test piece. A resonating rod is set into a longitudinal oscillation by multiple piezo elements, mounted to the upper end of the rod.The UCI Hardness Tester TCM-U2 operates according to the Ultrasonic Contact Impedance (UCI) method of hardness testing, and is standardized according to ASTM A1038 . The basic operating principle is that hardness is measured by detecting the frequency shift of a longitudinal oscillating rod fused to a Vickers diamond indenter.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

During the decades, various destructive and non-destructive hardness test methods have been developed. The non-destructive methods are portable and can be used on materials at the service, but a widely accepted non-destructive hardness test method, the ultrasonic contact impedance technique, is limited to measure the surface hardness. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range 1.1 This test method covers the determination of comparative hardness values by applying the Ultrasonic Contact Impedance Method (UCI Method). 1.2 The values stated in SI units are to be regarded as standard.The Ultrasonic Hardness Tester is a non-destructive ultrasonic testing method used to measure materials’ hardness. The principle of this instrument requires a tool (gauge). The tool will be applied to the sample on which a probe will be fixed and then this probe will send out ultrasounds which will determine the hardness of the sample.

ultrasonic hardness tester

Features: State of the art, digital ultrasonic portable hardness tester is designed to test the hardness of metal parts. Loaded with useful functions only found on high priced models the PHT-6000 series portable hardness testers are clearly setting a new industry standard by being the most accurate, comprehensive and versatile portable hardness testers on the market today. Contact and Immersion Testing. Ultrasonic testing can also be split into two main types: contact or immersion testing. Contact ultrasonic testing is typically used for on-site inspections accessibility or portability. Contact ultrasonic inspection can be performed where only one side of a test specimen as reachable, or where the parts to be .The UCI Hardness Tester TCM-U3 operates according to the Ultrasonic Contact Impedance (UCI) method of hardness testing, and is standardized according to ASTM A 1038. The basic operating principle is that hardness is measured by detecting the frequency shift of a longitudinal oscillating rod fused to a Vickers diamond indenter. Overview of Non-Destructive Hardness Testing Methods. Since hardness testing has multiple applications, the techniques vary a lot, too. The optimal test method depends on the tested item’s size, shape, texture, and .

ASTM A1038 Full Name. ASTM A1038 – Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method. Scope. This test method covers the determination of comparative hardness values by applying the Ultrasonic Contact Impedance Method (UCI Method).. Keywords

In the past few decades research work and development of testing procedures and equipment have been carried out to characterize microstructural and mechanical properties of materials by ultrasonic testing methods. Ultrasonic testing parameters are significantly influenced by variations in microstructural or mechanical properties of materials.

Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method1 This standard is issued under the fixed designation A1038; the number immediately following the designation indicates the year of original .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

The ASTM A1038 test method employs the Ultrasonic Contact Impedance Method (UCI Method) to determine comparative hardness values in metallic samples. This technique holds significant importance in various applications, including assessing the quality and hardness of surfaces that are difficult to access.Hardness testing devices with UCI measuring technology from NewSonic. NewSonic’s hardness testing devices test hardness in a nondestructive way using the UCI method (ultrasonic contact impedance). The testing procedure enables quick and mobile measurements (1-second type) to supplement traditional hardness testing.

Key hardness testing methods include Rockwell, Brinell, Vickers, Knoop, and Shore. Advanced methods consist of the Leeb rebound hardness test and the Ultrasonic Contact Impedance (UCI) method. Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International .

NewSonic once again proves its high competence in development of test devices and systems in UCI (Ultrasonic Contact Impedance) hardness testing technology. The SonoDur3 is exemplary in terms of a good overview and uncomplicated handling, just as its predecessor SonoDur2 was.

UCI (Ultrasonic Contact Impedance) for ultrasonic hardness testing. For this method the test indentation size that of the Vickers diamond is not evaluated optically but measured electronically when the corresponding test load is reached. This measurement process is performed in a fraction of a second.The SONODUR 3 provides two different technology standards for hardness testing: The UCI method (Ultrasonic Contact Impedance) and the Leeb method. The user-friendly SONODUR 3 is designed for rough everyday use. The mobile high-tech all-rounder is used for quality control at incoming goods or during the production process. Another field of .The MICRODUR instruments (Krautkramer) work according this method, the so-called UCI (Ultrasonic Contact Impedance) method. Another well-known principle for portable hardness testers is the rebound method. The DynaMIC and DynaPOCKET (Krautkramer), for example, measure the velocity of a propelled impact body directly before and after the impact .

The ultrasonic contact impedance (UCI) probe is purposed to be used for hardness measuring in the case of the testing area minimal thickness (from 1 mm), objects of complex surface shape, and for measuring surface hardened layers hardness. This method is very fast and easy: place the probe on the tested object surface, press the probe with the .

thailand drops test and go

ultrasonic contact impedance hardness tester

Inaugurado em maio de 2014, o IED Rio revitalizou um patrimônio histórico e cultural na praia da Urca, o charmoso e histórico edifício que abrigou o Cassino da Urca e a TV Tupi, ícones da cultura brasileira. O Rio de .

ultrasonic hardness testing method|ultrasonic contact impedance hardness tester